Welcome to SAMARTH ENGINEERS

Samarth Engineers combines expertise and innovation to power industries with precision-crafted solutions.

Where Quality, Trust, and Innovation Come Together

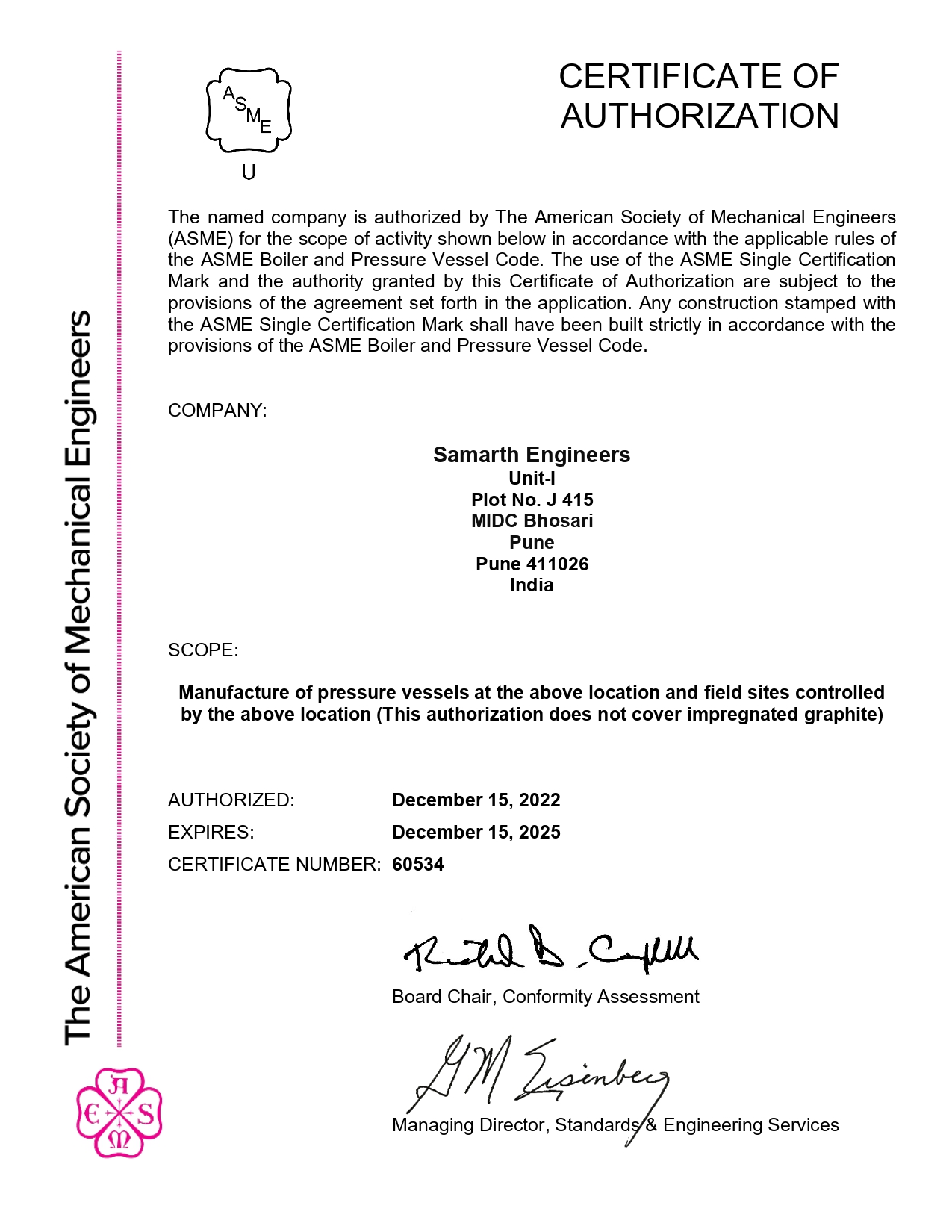

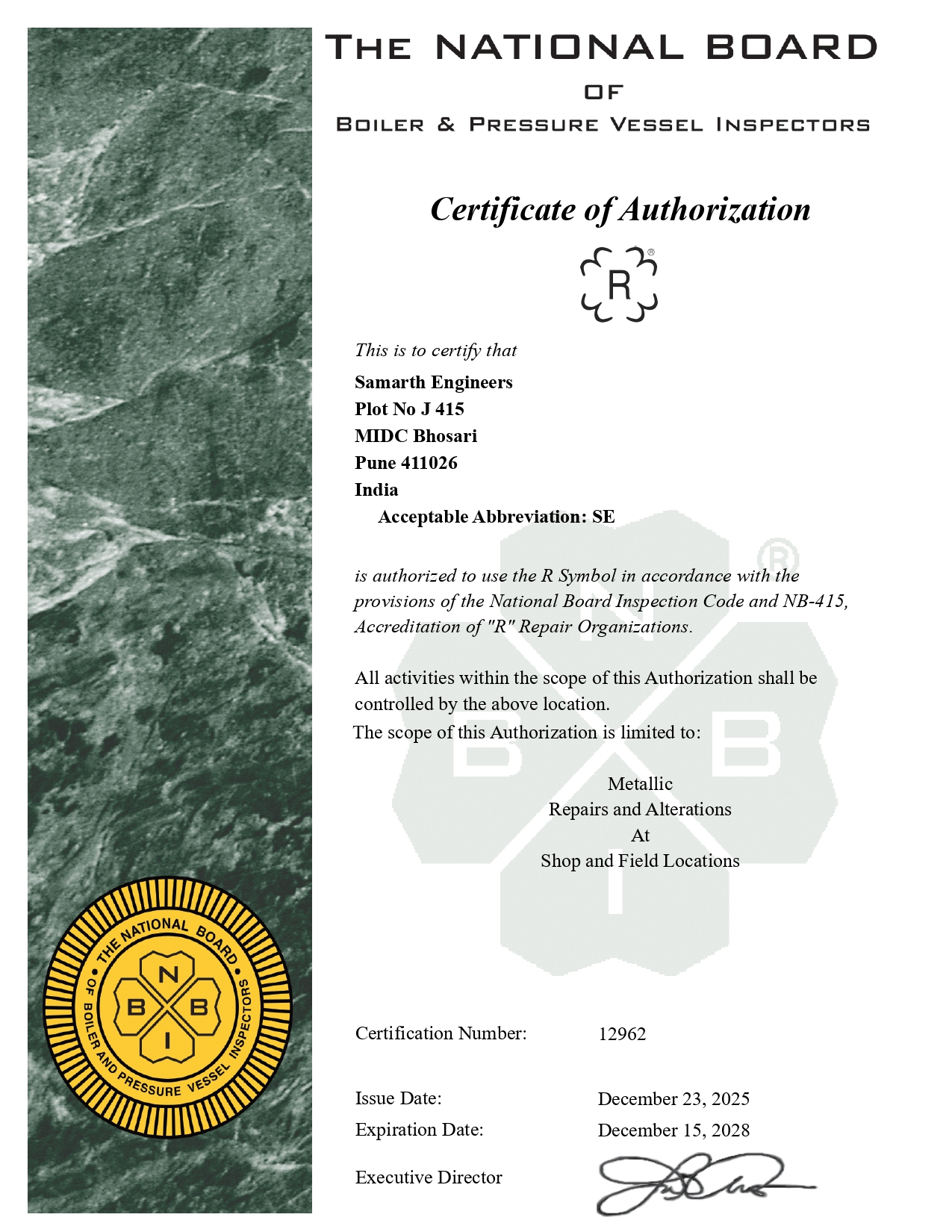

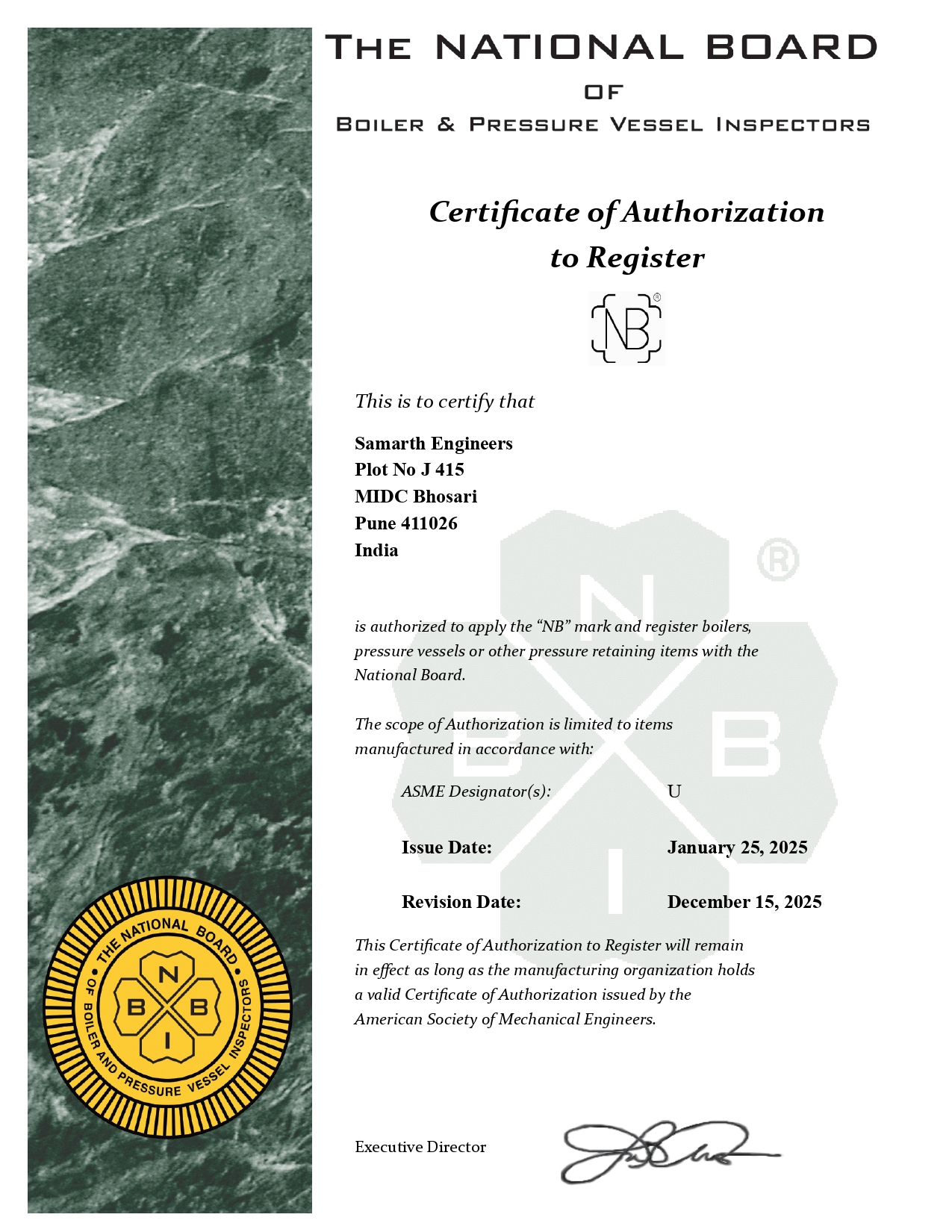

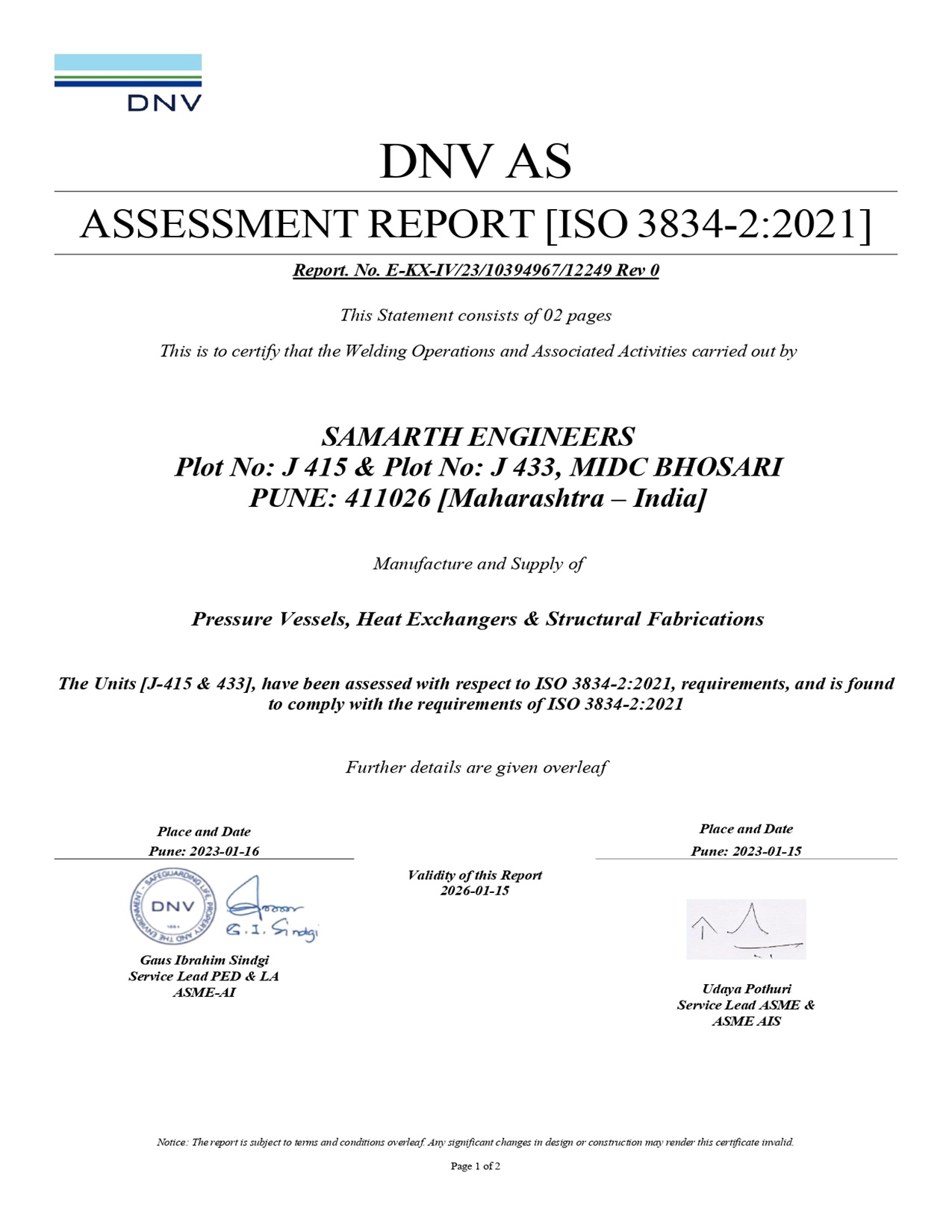

Samarth Engineers is a trusted name in the design and manufacturing of Hydraulic and Pneumatic Accumulators, Oil and Gas Separators, and U-stamp certified Pressure Vessels. Since our inception in 2005, we've been delivering high-quality, precision-engineered solutions for the demanding needs of the oil and gas industry.

Founded by Mr. Sanjay Raut, a passionate engineer and visionary, Samarth Engineers was built on a commitment to innovation, technical excellence, and uncompromising quality. Under his leadership, we have grown into a company known for on-time delivery, strict adherence to international standards, and products that perform reliably in the toughest environments.

24

Countries

200

Employees

200

Satisfied Client

SAMARTH ENGINEERS

Expertise & Experience

With years of hands-on industry experience, we bring deep technical knowledge and practical insights to every project.

1

Quality-Driven Approach

We never compromise on quality. Our processes follow strict quality standards to ensure superior performance and long-term durability.

2

Customized Solutions

Every project is unique. We tailor our solutions to meet your specific requirements, ensuring maximum efficiency and effectiveness.

3

4

Timely Delivery

We value your time. Our streamlined project management ensures on-time completion without compromising quality.

5

Customer-Centric Service

Your satisfaction is our priority. We build lasting relationships through transparent communication, responsive support, and dependable service.

6

Cost-Effective Solutions

We offer competitive pricing without sacrificing quality, helping you get the best value for your investment.

Woking Process For Technology

1. Feasibility check of RFQ

Evaluate RFQ for technical feasibility, timelines, and resources.

2. Pricing submission

Prepare and submit commercial proposal to the client.

3. Appointment of AI agency

Select and appoint the AI agency for the project.

4. Design data collection

Collect specifications, drawings, and material requirements.

5. Preliminary design calculations and drawings

Perform engineering calculations and prepare initial drawings.

6. Submission to AI and client for review

Submit preliminary design for feedback and review.

7. Modifications if required

Make changes based on review comments.

8. Re-submission

Submit revised drawings and calculations.

9. Approval from client and AI

Obtain formal approval from both client and AI agency.

10. Technical datasheet preparation

Prepare datasheets for all raw materials.

11. Material procurement

Purchase raw materials per specifications.

12. RM inspection

Inspect incoming raw materials for quality.

13. Fabrication begins

Start fabrication as per approved plans.

14. Intermediate processes

Conduct inspections, RT, LPT, UT, and hydrotests.

15. Final inspection

Perform final acceptance inspection.

16. Surface processing

Apply coating, painting, or passivation.

17. MDR signing

Complete MDR and perform U-stamping.

18. Dispatch

Prepare documentation, pack, and ship.

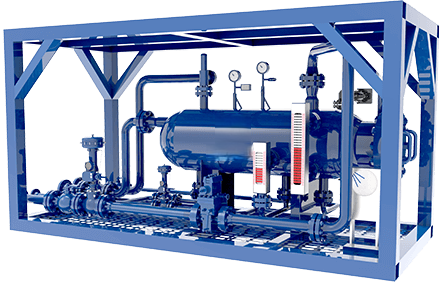

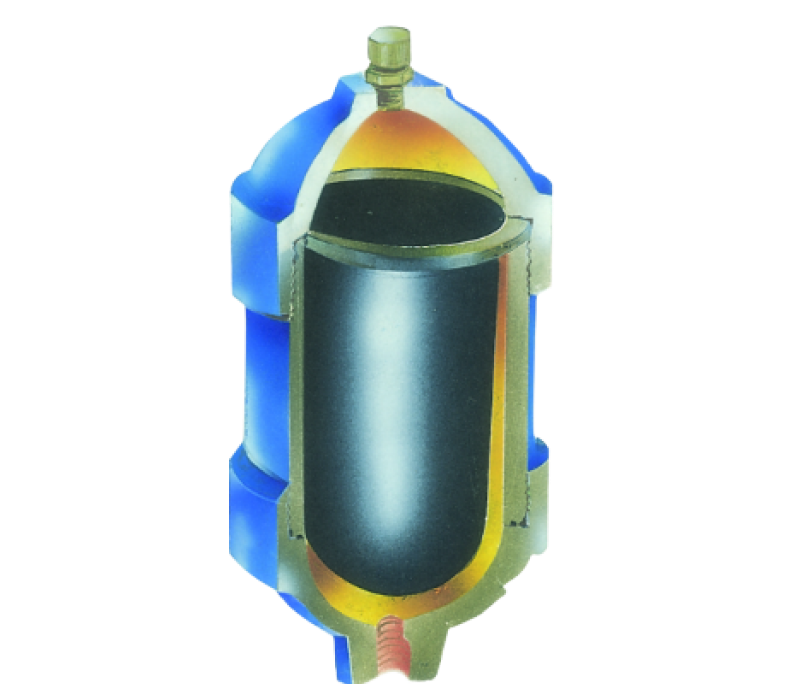

Accumulators

Bladder

Large Volume

Membrane

Screwed

Separator

Oil & Gas Production

Separator

900 PSI Test Separator

Separator

1440 PSI Test Separator

Separator

2160 PSI Test Separator

Sample cylinders & Volume bottles

Engineering Solutions That Work for You

Custom Engineering Solutions

Tailor-made engineering solutions to meet your project’s exact needs, from concept to completion.

Quality Testing & Inspection

Rigorous inspection and testing services to ensure products meet strict industry and client standards.

On-Time Delivery & Logistics Support

Reliable and timely delivery with complete logistics support to keep your project on track.